Manufacturing Facility

VinoD Weavings attributes a significant part of its success to the cutting-edge fabric manufacturing facilities situated across country. Some units are specialized mainly in weaving operations. In contrast, other factories are comprehensive facilities, encompassing yarn dyeing, weaving, and processing setups. This unique amalgamation of machinery enables the processing of fabrics crafted from various natural and synthetic fibers.

Within the same premises, we boast a spacious packing and warehousing facility, serving as a centralized dispatch center for all our fabric businesses. Additionally, we take pride in our Liquid Ammonia processing plant, the second of its kind in India and the fifteenth globally. The Liquid Ammonia treatment imparts a superior wrinkle-free finish to cotton fabrics. Commissioned in 2007, our factory strategically caters to both domestic and international dispatch requirements.

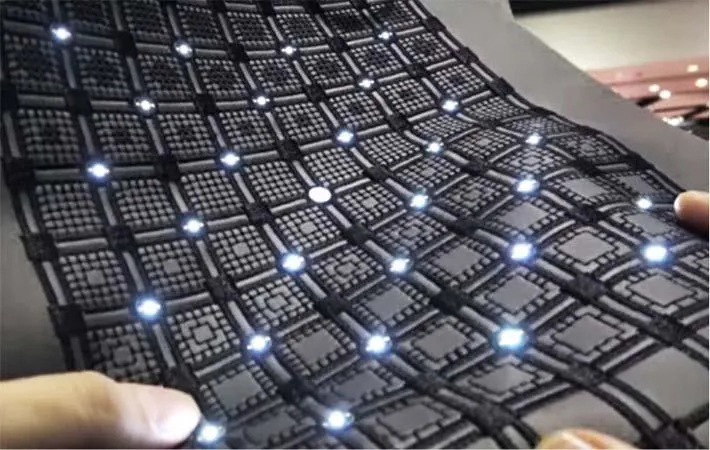

Machinery and Technology

A crucial factor contributing to the success of VinoD Weavings is our ongoing commitment to exploration, investment, and the utilization of cutting-edge technologies and machinery. We consistently strive to stay at the forefront of advancements in textile machinery and technology by actively participating in global exhibitions such as ITMA editions and Tech-textile.

In our operations, from yarn dyeing to the packaging stage, we rely on the latest versions of machines sourced from leading countries like Italy, Germany, and Switzerland. This dedication to incorporating state-of-the-art equipment ensures the efficiency and quality of our processes.

Quality Centre

The enduring success and longevity of VinoD Weavings rest on the foundation of unwavering quality maintained year after year. Consequently, our emphasis on quality and testing stands as one of our foremost priorities. Our fully-equipped quality lab is furnished with the latest testing instruments, meticulously calibrated on a regular basis. From the initial testing of raw materials, we ensure that only the highest quality materials are incorporated into our processes.

Implementing multiple check-points at various intermediate stages of the fabric manufacturing process, we subject the final fabric to comprehensive testing. This includes assessments for optimum shrinkage, strength, pilling, color fastness, and more. Every meter of the final fabric undergoes scrutiny through a 4-point check system, ensuring meticulous inspection, grading, packing, and dispatching according to established standards.

Design Centre

In the realm of fashion, the pivotal role of design cannot be overstated, influencing the success of both B2C and B2B brands. What distinguishes us is the cohesive team of design consultants at the forefront of our operations. They adeptly forecast trends, distill them, and strategically position them based on prevailing market sentiment and consumer preferences.

Our designers actively participate in major global fashion events like Premiere Vision and Texworld, consistently bringing the latest trends in design, fabric, and yarns directly to their drawing boards. This proactive engagement ensures that we stay abreast of global shifts in the fashion landscape, allowing us to offer innovative and on-trend solutions to our clients.

Innovations

Our robust Research and Development (R&D) team, coupled with advanced infrastructure, is dedicated to continually identifying the next market-winning innovations. From sample warping and dyeing to power looms, we operate a comprehensive system with a focus on quarterly and annual R&D projects. These initiatives encompass various facets of the product lifecycle, starting from the fiber level and extending to packaging.

Furthermore, we place significant investments in establishing a sustainable and eco-friendly textile value chain. Throughout the procurement process, intermediate stages, and final packing materials, we are committed to ongoing innovation. Striking the right balance between sustainability and costs, we strive to arrive at the most optimal solutions for a greener and more efficient approach to textile production.